Understanding the Significance of Light Weight Aluminum Spreading in Modern Production Processes

Aluminum spreading has emerged as a crucial part in modern manufacturing. Its light-weight and sturdy nature contributes substantially to numerous markets, from automotive to electronic devices. Additionally, innovations in casting strategies enhance manufacturing efficiency and quality. As suppliers seek cutting-edge options, the function of aluminum casting in sustainability ends up being increasingly important. This conversation will certainly explore the multifaceted relevance of aluminum casting and its implications for the future of manufacturing. What exists in advance in this evolving landscape?

The Benefits of Aluminum Casting in Production

Light weight aluminum casting offers countless benefits that boost its appeal in contemporary manufacturing processes. One significant advantage is its lightweight nature, which results in minimized power consumption and boosted fuel effectiveness in transport applications. In addition, light weight aluminum's superb corrosion resistance prolongs the life-span of cast products, making them much more resilient in various atmospheres. The material also facilitates complex geometries and elaborate layouts, allowing makers to develop parts that meet precise requirements.

Additionally, light weight aluminum spreading flaunts a fairly low melting factor, which saves power throughout the production procedure. This characteristic likewise makes it possible for rapid cycle times, raising general productivity. The recyclability of aluminum adds to sustainability efforts, as recycled light weight aluminum needs substantially less power to procedure compared to key aluminum. Jointly, these advantages position aluminum spreading as a necessary strategy in modern manufacturing, satisfying the demands for efficiency, performance, and environmental responsibility.

Applications of Aluminum Spreading Across Industries

While different materials are used in manufacturing, light weight aluminum casting has come to be an essential method across numerous sectors because of its flexibility and performance. This procedure is commonly used in the vehicle industry for creating lightweight engine blocks, transmission cases, and various parts that boost gas effectiveness. In the aerospace sector, aluminum casting is essential for developing elaborate components that need high strength-to-weight proportions, adding to boosted aircraft efficiency.

Moreover, the electronics sector counts on light weight aluminum spreadings for warm sinks and real estates, where thermal administration is vital for device durability. The construction industry also gains from aluminum casting in the type of architectural components and architectural components that incorporate aesthetic charm with sturdiness. Additionally, the durable goods market uses aluminum castings for cookware and showing off equipment, leveraging the material's outstanding deterioration resistance and aesthetic finish. Generally, aluminum casting offers as a foundation in contemporary production, sustaining diverse applications throughout various fields.

The Role of Aluminum Casting in Sustainability

Sustainability has come to be a focal point in making practices, and light weight aluminum casting plays a critical function in advertising ecologically friendly options. The process of light weight aluminum spreading is inherently sustainable due to the material's recyclability. Light weight aluminum can be recycled numerous times without losing its homes, greatly reducing energy intake and resources needs. This reusing procedure takes in only around 5% of the energy required for primary aluminum production, leading to a significant reduction in carbon emissions.

Additionally, light weight aluminum casting promotes the manufacturing of lightweight components, which add to energy effectiveness in various applications, particularly in the aerospace and automobile markets. Lighter cars consume much less fuel, further lessening ecological influence. Additionally, advancements in casting methods are enhancing product utilization, lowering waste in manufacturing procedures. As markets look for to straighten with sustainability goals, aluminum casting emerges as a viable remedy, supporting a circular economy and fostering liable production methods

Technical Developments in Light Weight Aluminum Spreading Techniques

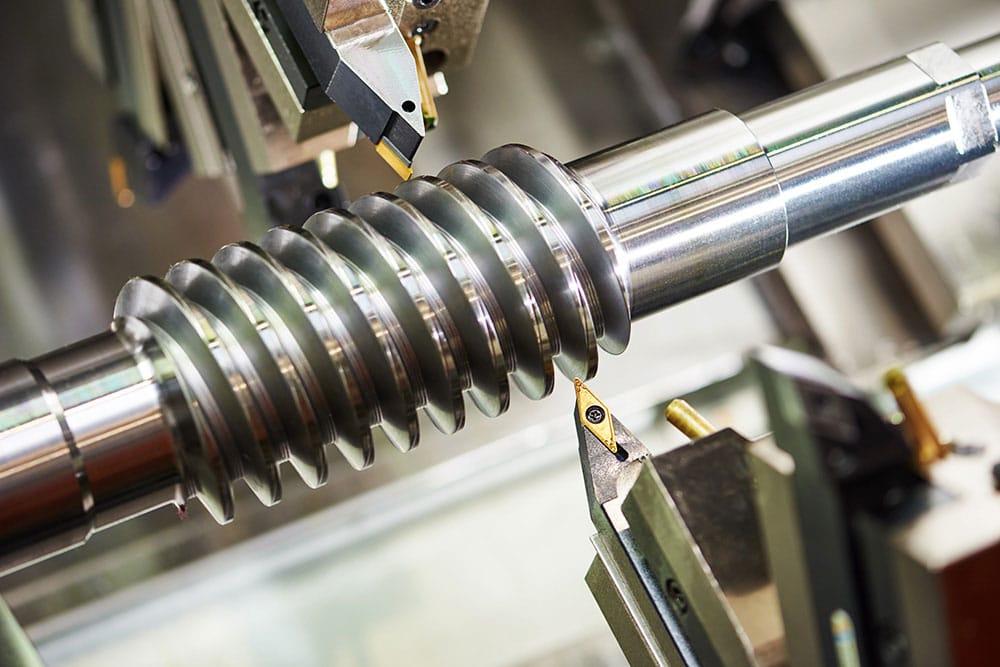

As sectors advance, the adoption of cutting-edge technologies in aluminum spreading strategies has changed producing procedures. The combination of computer-aided design (CAD) and computer-aided production (WEBCAM) systems boosts accuracy and efficiency, permitting intricate geometries that were previously challenging to produce. Advanced melting and spreading approaches, such as die casting and financial investment casting, have actually improved the quality of aluminum parts, lowering and lessening issues waste. Furthermore, the introduction of automated systems and robotics in casting operations has streamlined process and boosted efficiency. These developments likewise enable real-time monitoring and data analytics, helping with better decision-making and quality assurance. In addition, the advancement of new alloys and heat therapy procedures has broadened the efficiency capabilities of cast light weight aluminum products. Jointly, these technical innovations not only maximize manufacturing performance but likewise add to the sustainability of aluminum spreading in modern production.

Future Fads in Aluminum Casting and Its Effect On Technology

Arising trends in aluminum spreading are poised to improve the production landscape, driving advancement across different industries. One significant pattern is the integration of sophisticated automation and robotics, which boosts precision and efficiency in manufacturing procedures. In addition, the surge of additive production methods is permitting a lot more intricate styles, minimizing product waste and manufacturing time. As sustainability comes to be a concern, the market's concentrate on recycling aluminum and making use of environment-friendly methods is anticipated to expand, aligning with worldwide ecological objectives.

Moreover, the development of clever spreading innovations, including real-time surveillance and data analytics, is readied to improve quality control and operational performance. These advancements will certainly assist in the production of lighter, stronger, and a lot more resilient light weight aluminum parts, accommodating markets such as automotive and aerospace. Ultimately, these trends will not only optimize making procedures yet also inspire brand-new applications of light weight aluminum spreading, promoting a society of advancement and flexibility in the market.

Often Asked Inquiries

What Is the History of Light Weight Aluminum Casting in Production?

How Does Light Weight Aluminum Spreading Contrast to Other Metals?

Aluminum casting deals benefits such as lightweight buildings and deterioration resistance contrasted to other steels. aluminum casting. It improves and helps with intricate forms energy effectiveness, making it a preferred selection in different production applications over larger choices like steel or iron

What Are the Common Flaws in Light Weight Aluminum Spreading?

Common issues in aluminum casting consist of porosity, shrinkage, misruns, and inclusions. These concerns can emerge from inappropriate pouring techniques, poor mold style, or polluted materials, bring about diminished architectural stability and performance here of the last product.

Just how Is the High Quality of Aluminum Castings Tested?

The quality of aluminum castings is tested via methods such as visual inspections, dimensional measurements, non-destructive testing methods, and mechanical building analyses, ensuring that they meet defined standards for performance and structural stability.

What Are the Safety And Security Procedures in Light Weight Aluminum Spreading Processes?

Precaution in light weight aluminum spreading processes consist of using individual protective devices, proper air flow systems, normal devices upkeep, training employees on risks, and implementing strict emergency methods to lessen dangers linked with heats and liquified metal.

The recyclability of aluminum adds to sustainability initiatives, as recycled aluminum calls for substantially less power to procedure contrasted to primary aluminum. While different materials are utilized in manufacturing, aluminum casting has actually ended up being an essential approach throughout multiple markets due to its convenience and functionality. Advanced melting and spreading approaches, such as die spreading and investment casting, have boosted the quality of aluminum components, reducing defects and decreasing waste. Arising fads in aluminum spreading are positioned to improve the manufacturing landscape, driving advancement across different fields. Aluminum casting has actually advanced since the late 19th century, initially establishing with the introduction of light weight aluminum as a light-weight metal.